2011 KCSE Woodwork Past Paper

4.4.1 Woodwork Paper 1 (444/1)

SECTION A (40 marks)

Answer all the questions in this section

1 (a) List four safety attire required in a workshop.(2 marks)

(b) State four ways in which waste wood can be utilized.(2 marks)

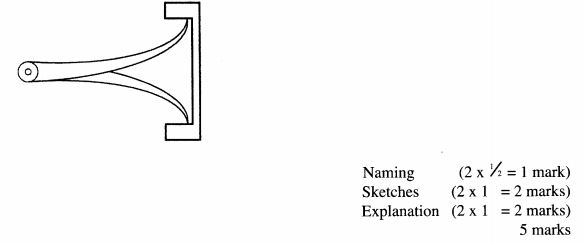

2 State four factors to consider when:

(a) making an order for plywood;(2 marks)

(b) determining the method of conversion of timber.(2 marks)

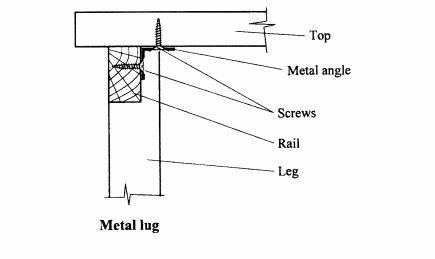

3 Figure 1 shows a hole drilled in a piece of timber.

Outline the procedure of drilling a hole using an expansive bit. (3 marks)

4 (a) Give two reasons for setting the saw teeth. (2 marks)

(b) Outline the procedure of setting the saw teeth. (2 marks)

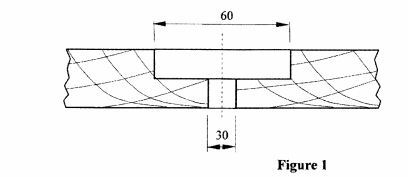

5 Figure 2 shows a defective blade of a jack plane.

2

Outline the procedure of reconditioning the blade. (4 marks)

6 With the aid of sketches, explain how the two types of calipers are used to take measurements. (5 marks)

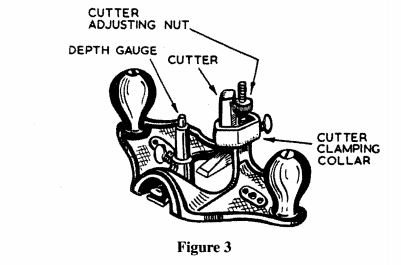

7 Figure 3 shows a tool used for cutting grooves

(a) Name the tool. (1 mark)

(b) Outline the procedure of cutting a groove using the too]. (2 marks)

8 Outline three faults which may occur when fitting hinges and state one effect of each fault.(6 marks)

9 (a) State one reason for using wood fillers. (1 mark)

(b) State two functions of wood stains. (2 marks)

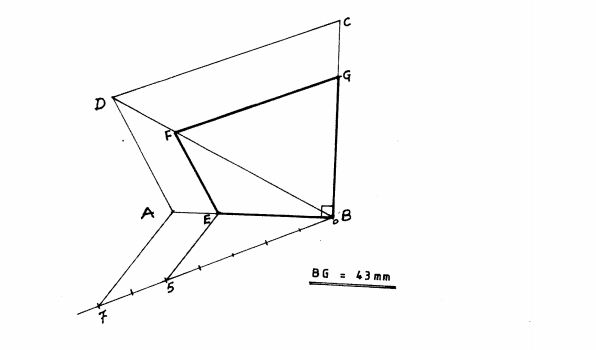

10 (a) Construct a quadrilateral ABCD of side lengths AB = 50mm, BC = 6Omm,AD = 40mm and angle BAD =l20″ and angle ABC = 90°. (1 mark)

(b) Reduce the quadrilateral in the ratio of 5:7. (2 marks)

(c) Measure the length of side BG in millimeters. (1 mark)

SECTION B (60 marks)

Answer question 11 and any other three questions from this section.

Candidates are advised not to spend more than 25 minutes on question 11.

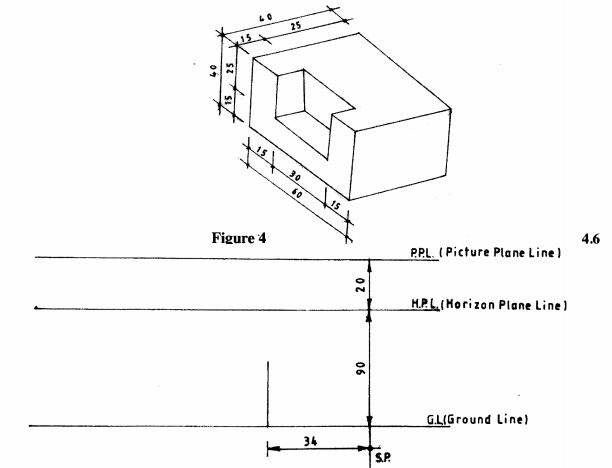

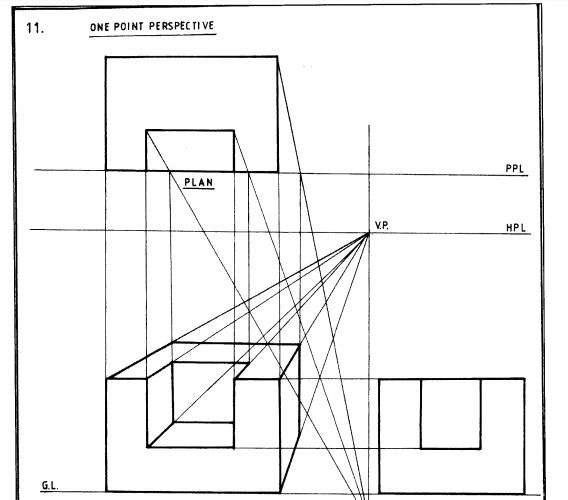

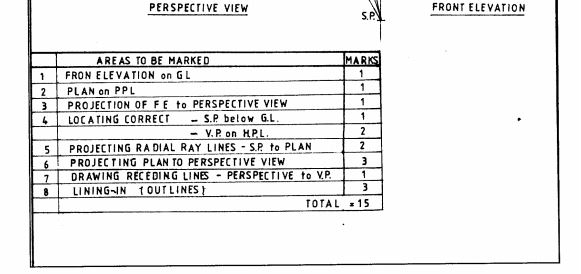

11 Figure 4 shows an object drawn in isometric projection.

Using the outline given. draw:

(a) the front elevation;

(b) the plan;

(c) one~point perspective view. (15 marks)

12 (a) Give two reasons for providing a groove in a 9mm diameter dowel. (2 marks)

(b) Outline the procedure of making a dowel using a metal plate. (5 marks)

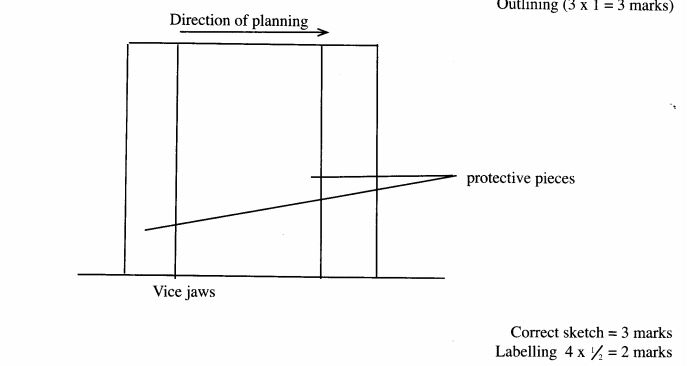

(c) With the aid of a labelled sketch, outline the procedure of planing the end grains of a work niece measuring 75mm wide. (8 marks)

13 (a) Outline the procedure of manufacturing chipboard from raw materials. (6 marks)

(b) With the aid of sketches, describe each of the following timber defects:

(i) cupping;

(ii) twisting;

(iii) diamonding. (9 marks)

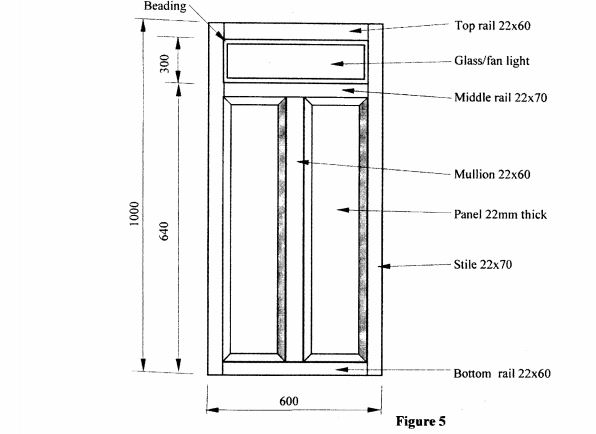

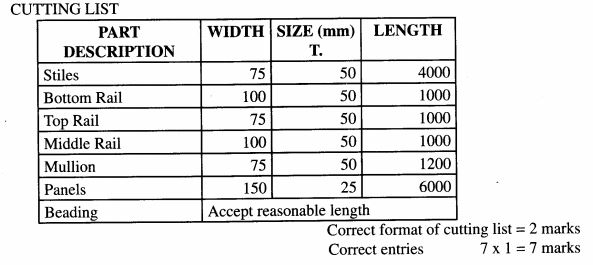

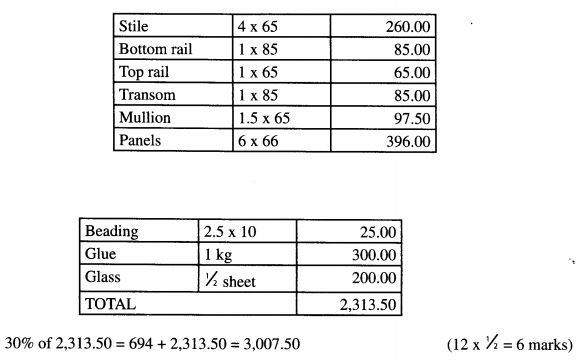

14 Figure 5 shows the elevation of a kitchen cabinet door.

a) Prepare a cutting list for the materials required for the construction of the door. (9 marks)

(b) Estimate the cost of the door given the following price list:

Cost per 300mm 75 x 25 = 40/-

150 x 25 = 66/-

Glue 1kg = 300/-

Glass 300 X 300 X 5 = lOO/

Beading 15 X 15 = 10/

Allow 30% for labour and overheads. (6 marks)

15 (a) Outline the procedure of painting a new wood surface. (4 1/2 marks)

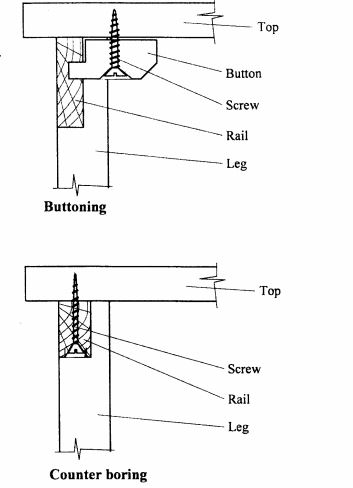

(b) Using labelled sketches, show three methods of fixing a table top to a rail.

(10 1/2 marks)

2011 KCSE Woodwork Past Paper-Marking Scheme/Answers

21.0 WOODWORK (444)

21.1 Woodwork Paper 1 (444/1)

1 (a) SAFETY ATTIRE

(i) Apron/overall

(ii) Gloves

(iii) Goggles

(iv) Helmet

(v) Boots

(Any 4 x 1/2 = 2 marks)

(b) UTILIZATION OF WASTE WOOD

(i) Fuel

(ii) Toys

(iii) Ornament

(iv) Manufactured board

(Any 4 x 1/2 = 2 marks)

2 (a) ORDER FOR PLYWOOD

(i) Number of veneers

(ii) Surface finish

(iii) Face veneer type

(iv) Nominal thickness

(v) Sheet size

(Any 4 x 1/2 = 2 marks)

(b) METHOD OF CONVERSION

(i) Log size/diameter

(ii) Type of Wood

(iii) Structural defects

(iv) Timber use

(v) Type of sawing machine

(vi) Proportion of heartwood to sapwood

(Any 4 x 1/2 = 2 marks)

3 DRILLING HOLE USING EXPANSIVE BIT

(i) Locate and mark the centre position of the hole (1/2 mark)

(ii) Set the expansive bit at 0 60 mm and drill hole midway (1 mark)

(iii) Set the bit at (5 30 mm and continue drill the hole till the screw tip shows on the other side. (1 mark)

(iv) Turn the work and finish drilling from opposite side (2 mark)

4 (a) REASONS FOR SETTING SAW TEETH

(i) To provide a ken” which is wider than the saw blade

(ii) To prevent blade from jamming when sawing

(2 X 1 = 2 marks)

(b) SETTING SAW TEETH

(i) Mount the saw blade between holding block and fix in a vice

(ii) Select appropriate setting tool

(iii) Bend every alternate tooth in one direction and the remaining teeth in opposite direction

(iv) Check to confirm alignment of teeth.

(Any 4 x 1/2 = 2 marks)

5 RECONDITIONING THE BLADE

(i) Set the correct grinding angle (20 – 25°) on the grinder

(ii) Grind the blade square till the nicks disappear

(m) Hone the cutting edge to correct sharpening angle (25 – 30°)

(iv) Flip the blade to remove the burrs at the back

(4 x 1 = 4 marks)

6. The outside calipers is used to measure external diameters of shafts as shown.

The inside calipers is used to measure internal diameters of holes as shown.

7 (a) Router plane (1 mark)

(b) PROCEDURE

(i) Select the correct size of the cutter

(ii) Mount the cutter

(iii) Mark the location of the cut

(iv) Cut the groove

(Any 4 x Z = 2 marks)

8 HINGE FAULTS

Protruding screw heads

Door will not close fully or screws will dig into its edge

Hinge set too far inside

Door carcase will bend on outside edge

Recess cut too deep

Screws will loosen on closing the door

Recess cut too shallow

A gap will be left between the door and carcase

Recess being out of square

Door will not align with carcase (any 3 marks)

9 (a) REASON FOR USING WOOD FILLERS

To cover cracks, dents, gaps etc. on Wood surfaces.

(b) FUNCTIONS OF WOOD STAINS

(i) Bring wood surface to desired colour

(ii) Bring out the beauty of the grains

12 (a) REASONS FOR GROOVE IN A DOWEL

(i) To allow air to escape while driving a dowel

(ii) To allow excess glue to flow out when driving a dowel

(b) PREPARING A DOWEL

(i) Prepare a square piece with sides slightly larger than required diameter

(ii) Taper one end of the square piece

(iii) Select the correct size of the hole on the plate

(iv) Drive the square piece through the hole

(v) Cut to required length of the dowel

(5 x 1 = 5 marks)

(c) PLANNING THE END GRAINS

(i) Clamp protective pieces level with the top of the Work piece

(ii) Mount the work in a vice allowing sufficient height for planning

(iii) Plane the end grains with a block or smoothing plane

Outlining (3 x 1 = 3 marks)

13 (a) MANUFACTURING CHIPBOARD

(i) Chip the raw material

(ii) Dry the wood particles

(iii) Grade the particlesinto sizes

(iv) Blend of mix With a suitable binder

(v) Form the board and press the board applying sufficient heat and pressure

(vi) Cut the board to size

(6 X 1 mark = 6 marks)

(b) TIMBER DEFECTS

(i) Cupping

This is the distortion of timber from a square cross section to a rhombus cross section. Caused by differential shrinkage

(ii) Twisting

This is the distortion of timber from a rectangular cross section to a concave cross section caused by shrinkage and stacking while drying.

(iii) Diamonding

This is the spiral distortion where a length of timber raises from normal flat run. Also known as ‘wind’ caused by lack of uniform pressure on boards when seasoning.

Sketch 1 1/2 marks Description 1 1/2 marks (3 x 3 = 9 marks)

14 (a) CUTTING LIST

(b)

15 (a) PAINTING A NEW SURFACE

(i) Prepare the surface by planning and sanding (1)

(ii) Apply the first coat or the priming coat (1)

(iii) Seal all the cracks, dents etc. (1)

(iv) Apply the undercoat and allow to dry (1)

(v) Apply the final coat (1/2)

(Total 4 1/2 marks)

(b) i